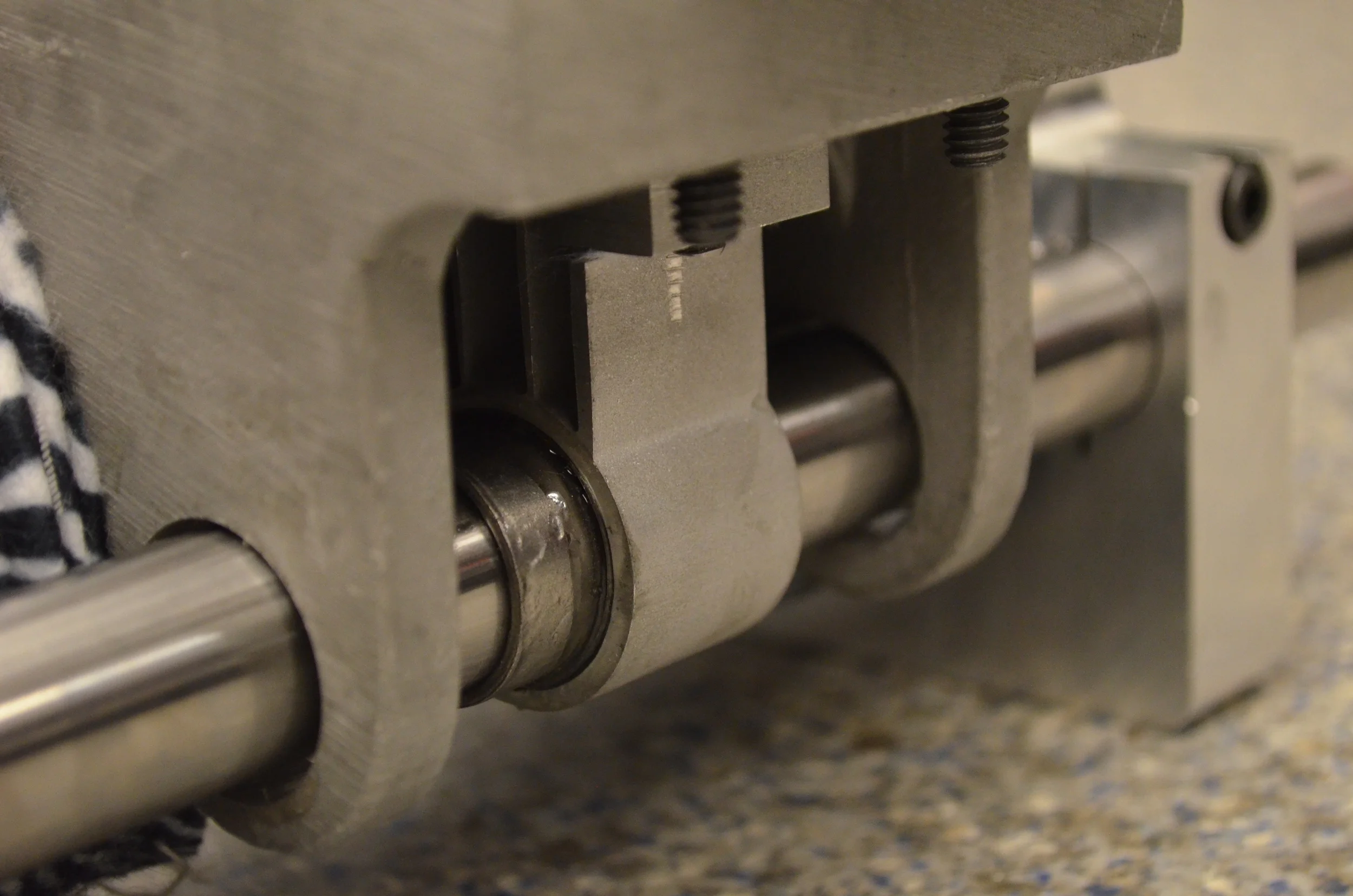

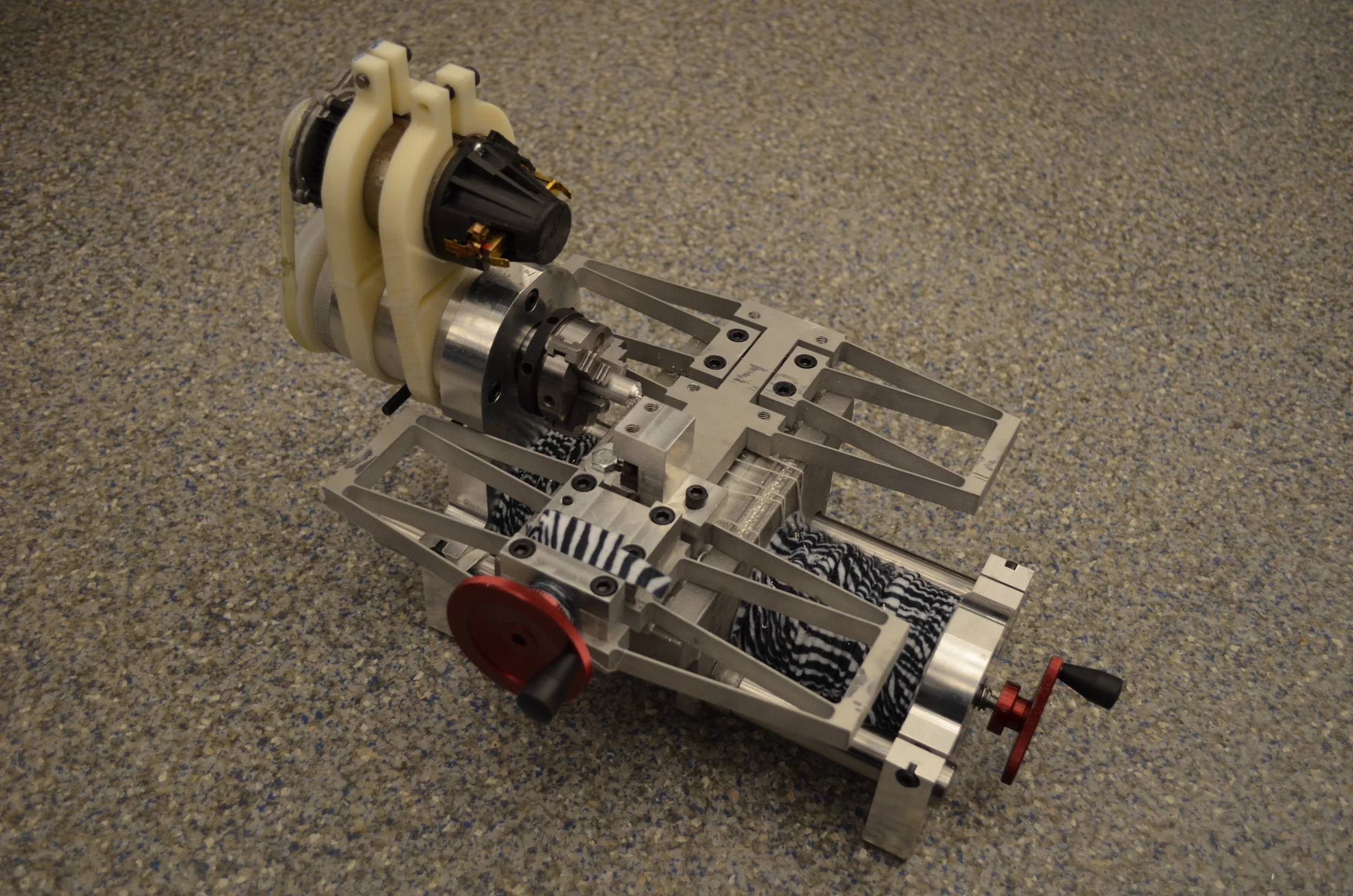

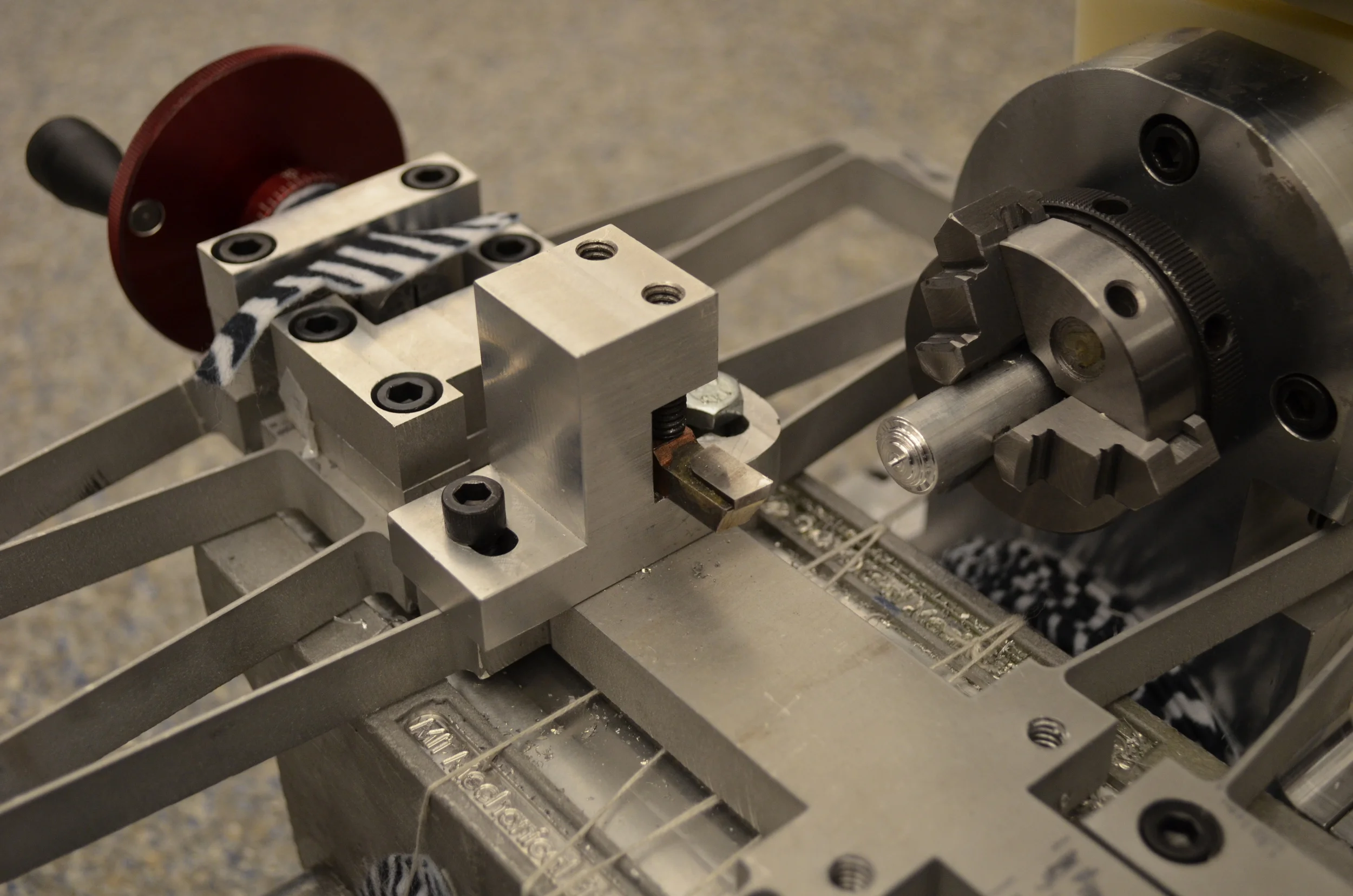

I worked with a team of 6 to design and build a desktop lathe that could cut aluminum stock within 50 microns accuracy and withstand a 1 meter drop test. Core mechanical engineering principles were applied to determine appropriate bearing fits and preloads for the lathe spindle, design flexures for the cross-feed, screw carriage, and rail carriage, and fabricate parts using precision machining and measurement techniques.

Our final project report includes more of our key findings throughout the project.

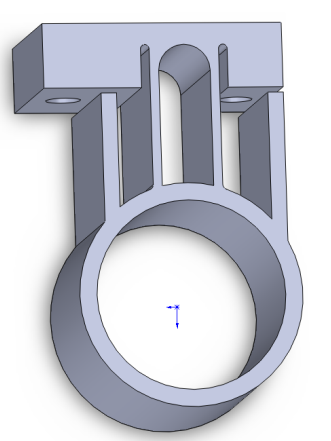

FLEXURE

I designed a flexure to constrain the motion of the carriage along the rails, using straight beam bending and finite element analysis (FEA) for design optimization. The final design used a “double blade” to provide a linear constraint, and thicker elements were added to divert the load path from the thin flexure blades in case of high loads or impulses.