FreeRim was a student project that developed a new propulsion method for wheelchair users that keeps users’ hands clean. Working on a team of 12 students, I built sketch models for concept testing, led design for an ergonomic handle, and engaged with customers to understand their needs. FreeRim was built for an intensive MIT capstone class where students make a working alpha prototype of a new product. The course culminates in a final presentation in front of a live audience of 1300. Based on the results of audience feedback, FreeRim placed first in technology and quality of prototype.

IDEATION

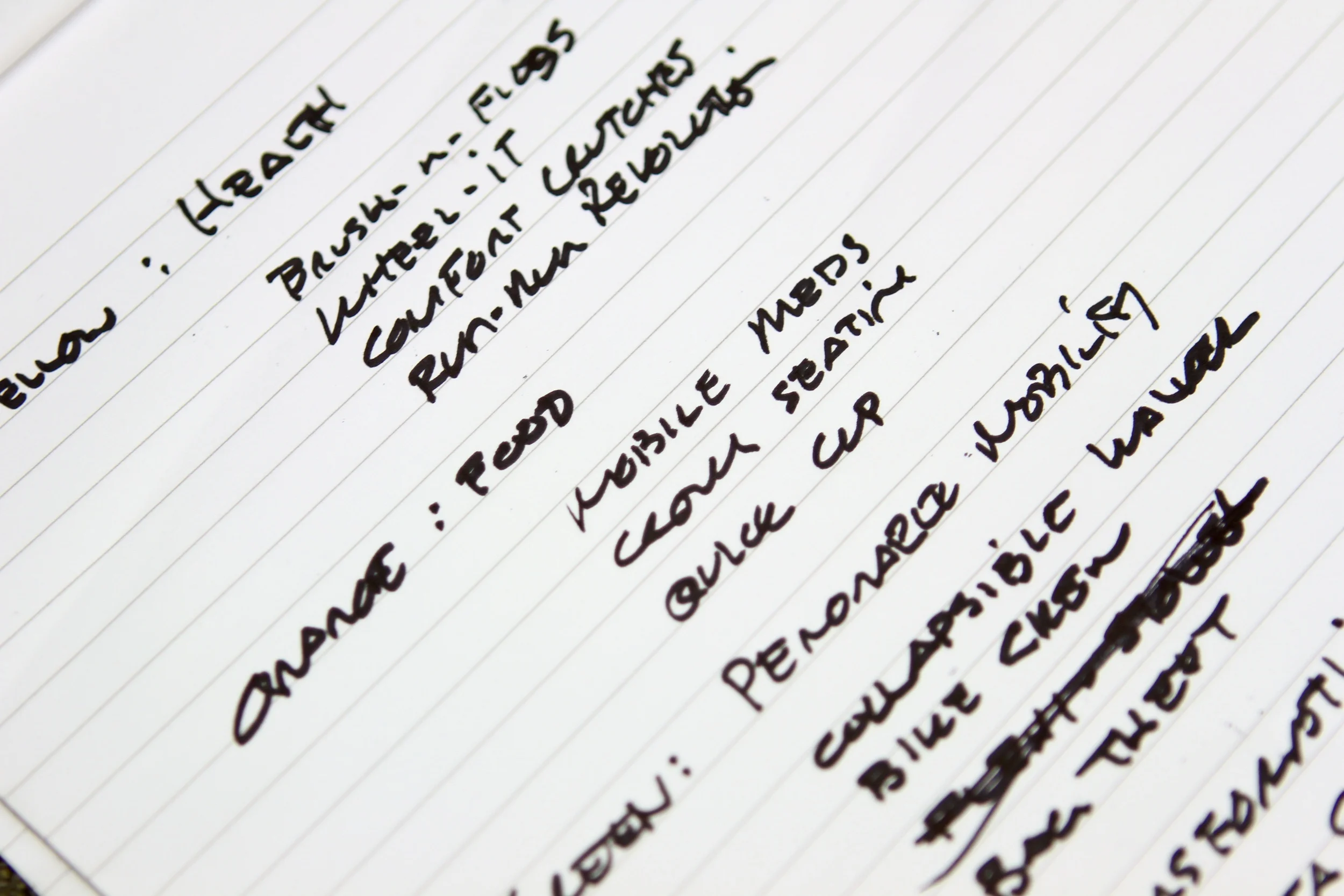

I used brainstorming and customer observation exercises to identify potential product opportunities. Market research and benchmarking exercises were utilized to rate technical feasibility of each product and whether a clear customer need was being addressed.

SKETCH MODELS

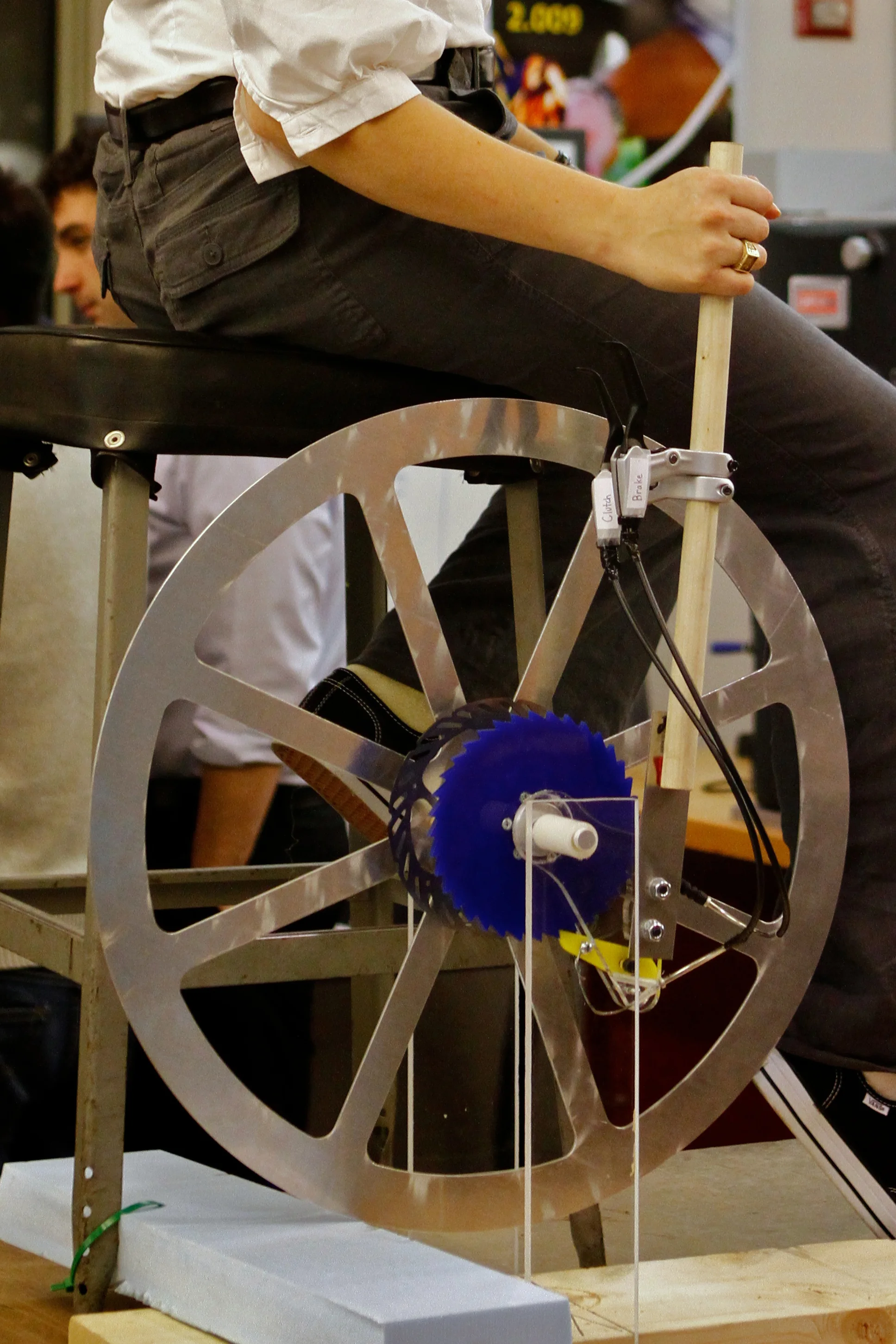

In the sketch model phase, I created waterjet and lasercut parts to generate a proof of concept of a propulsion mechanism that used a ratcheting clutch to go forward and a disk brake to stop. The mechanism went through a number of rounds of refinement before settling on using a disk brake to both propel and stop the device.

ERGONOMIC GRIP DESIGN

I led design and prototyping for an ergonomic handle. After researching human factors design, a set of prototypes were mocked up in foam and clay and were tested with customers. Once a basic design was selected, the handle was modeled in SolidWorks and a prototype was 3D printed for further testing. Based on customer feedback, the handle geometry was modified to allow the hand to more comfortably press against it during forward motion.

Testing early foam prototypes

Final handle CAD model

UNDERSTANDING CUSTOMER NEEDS

Throughout the project, many interviews and tests with customers were conducted to understand the range of motion required to propel a wheelchair, and develop a handle mechanism that would be compatible with users’ movements (for example, an early prototype required a constant grip on the propulsion mechanism, which was incompatible with the quick “stroke” motion that a key customer used to move her wheelchair forward).