I’ve been really excited about Klum House making kits and bought this little pouch as a dry run for a larger bag I’m planning to make.

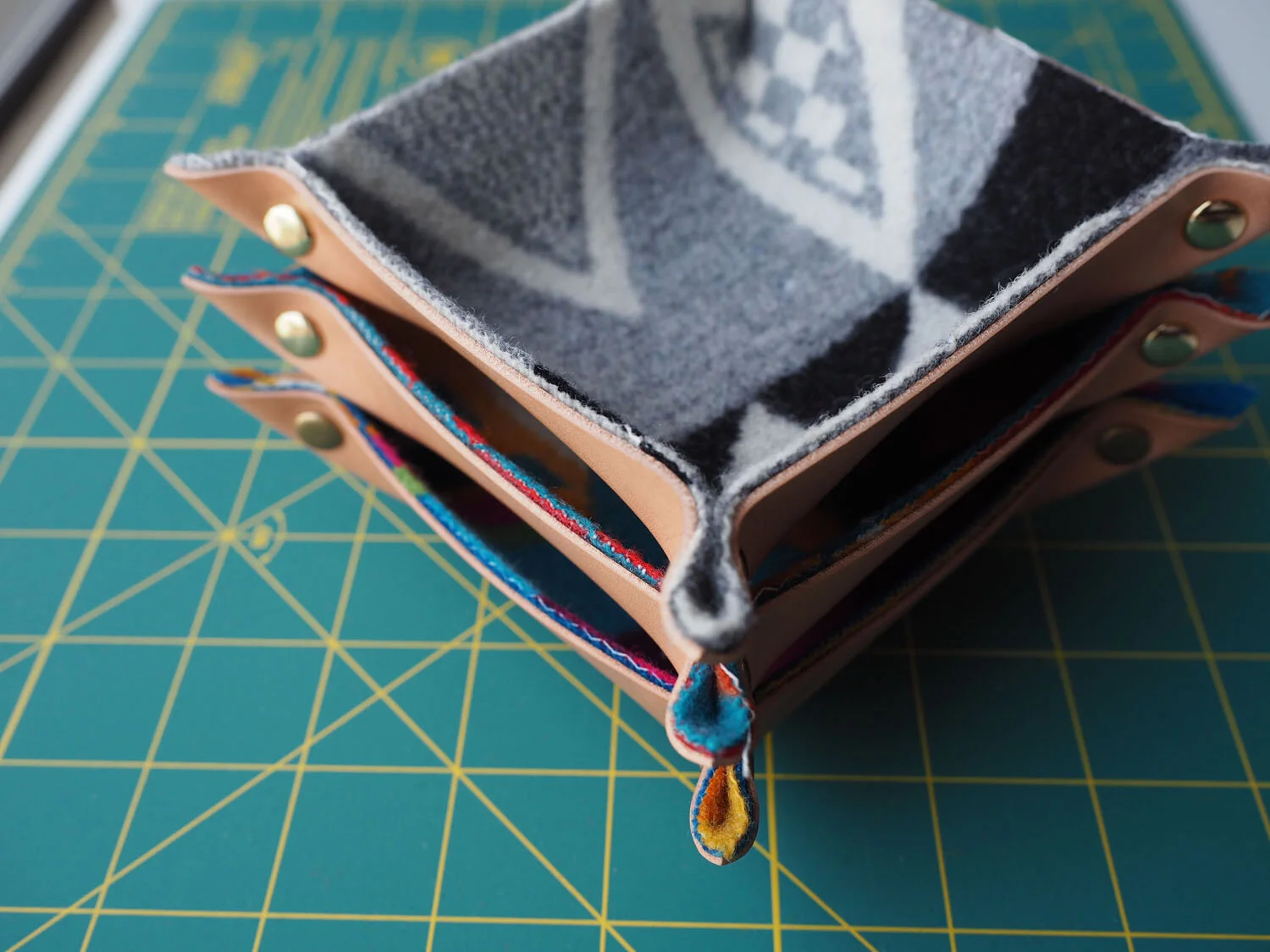

Pattern: Waxed canvas pouch kit by Klum House

New skills: Installing a zipper, sewing a lining, bagging out a lining

Lessons: Folding the edges of the zipper tap will create a cleaner finish.

Use only fine pins or wonder clips to hold the edges of waxed canvas as large pins will damage the material and compromise its water resistance.

Make sure the zipper is open before sewing in the lining, or it will be a huge pain to bag it out (you’ll have to open the zipper from the wrong side inside the bag.

Move the zipper out of the way while sewing the zipper tape—it can get in the way of the presser foot and cause the tape to be distorted.

What I’d do differently: I tapped the rivet a little bit aggressively so it has a small dent.

Care: Spot clean